What Is the Difference Between Single-Screw and Twin-Screw Pipe Extrusion Machines?

The pipe extrusion machine is an essential component when it comes to manufacturing plastic pipes, as it melts, shapes, and forms the needed raw materials into pipes of numerous specifications. Within this machine category, single screw and twin screw models are the most common. Many pipe extrusion machine manufacturers fail to recognize the definitional difference between the two which, in turn, complicates selecting the most suitable machine for their production process. This blog will highlight the key differences between single screw and twin screw pipe extrusion machines, focusing on the principles of operation, efficiency in production, versatility in material application, and other relevant parameters, to aid you in understanding these differences for your best purchasing decisions.

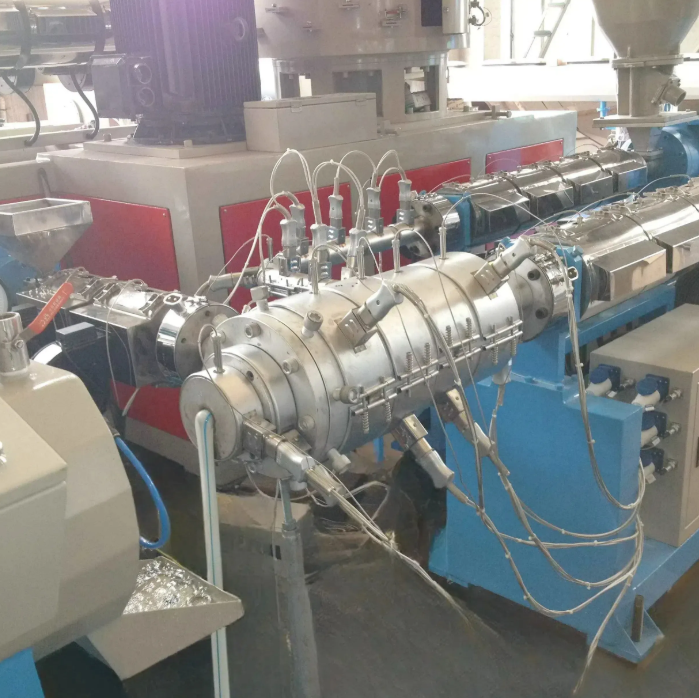

Difference 1: Operation Principle of Single-Screw and Twin-Screw Pipe Extrusion Machines

The most important distinction that separates single screw and twin screw pipe extrusion machines are principles of operation, which, in turn, influences the machines' capacity for processing materials. A single screw pipe extrusion machine simply contains one rotating screw in the barrel.

The process is quite straightforward. The screw rotates to move the plastic raw materials from the feed port to the extrusion die. The materials are heated to a liquid state by the heat of the barrel and the shear force of the screw. The melted materials turn to pipes through the die. Unlike this, a twin screw pipe extrusion machine has two screws that are intermeshed. The two screws can turn in the same or opposite direction. Regardless of the design, this permits the screws to convey, heat and shear materials and to improve the mixing and plasticizing of materials as a result of mutual extrusion and shearing. This explains why the two styles of pipe extrusion machines differ in the quality of material plasticization.

Difference 2: Pipe extrusion machines: Production efficiency and output.

With respect to the output and production efficiency of a pipe extrusion machine, the manufacturer’s choice is greatly influenced by these two parameters in the twin screw and single screw design. The difference in production efficiency and output between twin screw and single screw models is notable.

A single screw pipe extrusion machine is easier to make but has a more limited top speed (generally 30-60 rpm). Because one screw has even less horizontal conveying and plasticizing capacity, such machines have a lower output. For example, a single screw pipe extrusion machine produces 50-100 kg of 50 mm diameter PVC pipes in one hour. In contrast, a twin screw pipe extrusion machine enjoys the benefits of screw synergy–-higher top speeds (100-150 rpm) and greater material conveying capacity. For example, a twin screw pipe extrusion machine produces 150-300 kg of 50 mm PVC pipes in one hour, 2-3 times the output of the single screw model. For mass production, a twin screw pipe extrusion machine is more efficient overall.

Difference 3: Adaptability to Raw Materials of Pipe Extrusion Machines

A single screw pipe extrusion machine is more suitable for processing pure and low-viscosity plastic raw materials, such as ordinary PVC, PE, and PP. The adaptable design is processing various raw materials for input. This is easier to do with a twin screw pipe extrusion machine in most cases.

The processing capabilities for certain materials, especially those with high filling content, such as calcium carbonate filled pipes, and composite materials, like plastic pipes with glass fiber, is limited. This is due to an insufficient mixing ability of the components in a single screw extrusion, and challenges in achieving a uniform distribution of fillers and additives in the base materials, thus potentially compromising the quality of the finished pipe. A twin screw extrusion, with its enhanced mixing and shearing capabilities, offers a wider range of processing options. It can handle not only the basic plastic raw materials, but also high-filling reinforced addition and super-modified plastic materials. For instance, in the production of plastic pipes with a 40% filling of calcium carbonate, a twin screw extrusion is able to provide uniform filling and concentration of calcium carbonate, while a single screw extrusion will produce pipes of uneven concentration, causing weakness and a poor structural integrity.

Difference 4: Pipe quality and stability of the extrusion process

The quality and stability of the pipes produced will determine the market edge of the manufacturers, and in this regard, the two types of pipe extrusion machines differ significantly as well.

Given how a single screw pipe extrusion machine works, it may fail to completely melt and evenly heat the raw materials resulting in defective pipes. This may include the formation of bubbles, walls with varying thickness, and lack of surface smoothness. There is also the problem of poor screw conveying stability, where random changes to screws and material input lead to varying dimensions of the pipe being produced, affecting the uniformity of the end product. In contrast, a twin screw pipe extrusion machine excels in plasticizing and uniform mixing, ensuring pipes with smooth surfaces and uniform wall thicknesses. Furthermore, owing to more advanced conveying, the twin screws minimize fluctuations in pipe dimensions, providing uniformity throughout the batch. For pipe product manufacturers, the twin screw pipe extrusion machine is the optimal choice.

Difference 5: Equipment Investment and Operating Costs of Pipe Extrusion Machines

When it comes to pipe extrusion machines, the two models clearly differ in equipment investment and operating costs and these are important considerations for manufacturers.

With respect to equipment investment, twin screw extrusion machines cost upward of 2-4 times more than single screw machines because of their more complex structures (i.e., two screws, advanced transmission systems, and reinforced barrels). This makes single screw machines more attractive to small and medium-sized manufacturers who typically have more modest budgets. From an operational perspective, twin screw machines incur greater maintenance and energy costs because two screws have to be driven, and complex maintenance cycles are required. Despite this, the lower unit cost of pipes produced and higher volume output typically justify the investment in a twin screw extrusion machine without compromising product quality in high volume production. Ultimately, manufacturers need to consider the production scale for cost effective balancing of equipment investment against long term operational costs.

Conclusion

As outlined in the preceding sections, single screw and twin screw pipe extrusion machines have different principles of operation. This results in differences in production efficiency, material adaptability, quality of pipe produced, and the overall cost of production.

A single screw pipe extrusion machine is ideal for small production runs, working with basic materials, and budget-constrained small manufacturers. In contrast, twin screw pipe extrusion machines are better for large production runs, working with sophisticated materials, and manufacturers targeting superior quality and greater efficiency. Recognizing these distinctions helps in selecting the appropriate pipe extrusion machine tailored to your production requirements. If you would like more information based on your value-adding single screw and twin screw pipe extrusion machine needs, please check our site at https://www.bxkm.com/ for more details on our professional products and tailored services.