What Types of Rubber Materials Can a Professional Rubber Separator Machine Process?

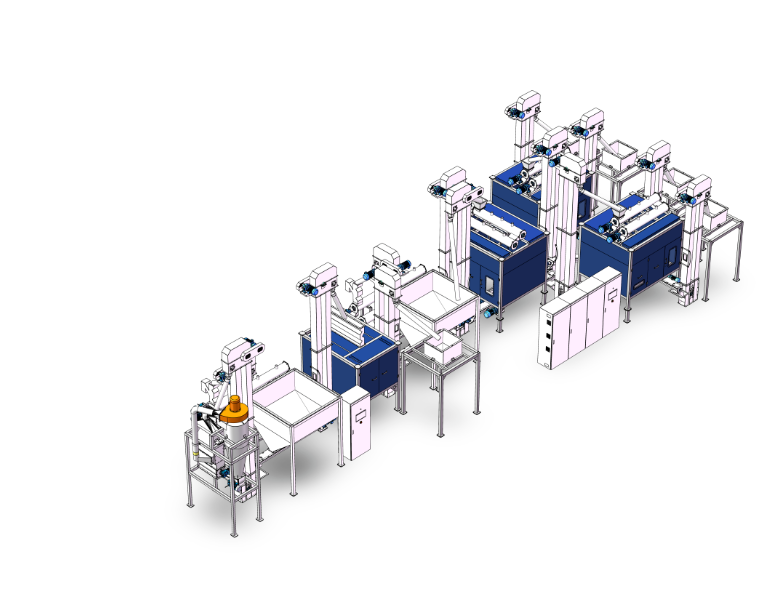

A rubber separator machine is pivotal in the recycling system and rubber processing industry. It classifies and cleans rubber materials and sets the stage for quality recycling and reuse. In the past 26 years, Baixiong Klimens developed a wide range of plastic and rubber processing machinery including adaptable and industrious rubber separator machines that tackle almost any type of rubber and cater to diverse industrial needs in any rubber recycling scenario. In this blog we will highlight the different kinds of rubber materials a rubber separator machine can work with, as well as the benefits of the Baixiong Klimens' systems.

Recycling Household Waste Rubber

A rubber separator machine can handle waste rubber from everyday household items. Waste products include rubber gloves, rubber sandals, rubber mats, and rubber gasket sealing rings used in household appliances. Household waste rubber products can come in different conditions and can become contaminated with dust, fibers, and tiny bits of metals. The rubber separator machine from Baixiong Klimens has a multi-stage sorting system. It first uses a crushing module to break down the waste rubber. Light contaminants like dust and fibers are removed by wind separation and vibration screening. Tiny metal fragments are eliminated later with magnetic separation. When it processes old rubber gloves, for instance, the system can cleanly separate pure rubber from the fabric linings and other mixed materials. Since much of the daily waste rubber can be processed and recycled, pollution is greatly reduced.

Industrial Rubber Scrap

During industrial production, a significant quantity of rubber scrap is generated, and a professional rubber separator machine effectively handles this type of material. Industrial rubber scrap is primarily composed of discarded rubber hoses, rubber gaskets, conveyor belts, and rubber components from devices and machinery. These rubber components tend to be more robust, thicker, and harder, and they can have oil stains, metal brackets, and mixed plastic impurities. Kliment’s Baixiong separator machine is equipped with a crushing mechanism capable of rendering thick industrial rubber scrap into smaller components. The machine has a unique pod designed to remove oil stains and dirt from rubber using high-pressure water jets. The machine then employs density separation technology to remove metal brackets and other impurities that are heavier rubber is then separated from the metal. In the case of rubber conveyor belt scrap, the system separates the top rubber layer and releases the internal rubber skeleton metal for recycling. This completed the recycling of industrial rubber.

Rubber from Waste Vehicles

There are other types of waste rubber that can be processed by professional rubber separator machines. This includes waste rubber tires, rubber tubes, and rubber seals from vehicles. Waste tires are vehicle rubber waste of high volume and complex structure. In addition to rubber, they contain steel wires and fabric layers. Waste tires processing requires high capacity rubber separator machines. Rubber separator machines of Baixiong Klimens include special tire crushing and separation lines. To begin, waste tires are cut into small blocks by a tire cutter and then a crushing machine breaks the blocks to rubber particles. They are then processed with magnetic separation to pull out the steel wires embedded in the rubber particles. The rubber particles are processed with air separation to get rid of the fabric fibers and rubber. This complex waste tire rubber separation process results in highly pure rubber that can be used for recycled rubber rubber paving materials and rubber mats. This vehicle rubber processing solves the problem of waste rubber tire accumulation and its processing promotes the circular economy.

Processing Medical Waste Rubber

Rubber separator machines can choose to process rubber medical waste as long as they comply with proper medical waste hygiene and safety standards. Medical waste rubber can be waste rubber gloves, rubber syringes, rubber gaskets of medical devices, and other rubber items associated with medical use. These rubber materials can also be medical waste and are residual contaminated materials that need to be treated to avoid environmental and medical risk exposure. Baixiong Klimens' rubber separator machines for medical waste rubber come with a high temperature closed loop disinfection module and closed loop processing systems. The high temperature closed loop module disinfector also kills remaining surface harmful bacteria and viruses. The closed loop disinfection and processing control systems contain and eliminate the escape of harmful emissions. After disinfection, the rubber is also crushed and separated to eliminate the remaining impurities of any plastic and other metallic components. The end result is a pure rubber that can be used safely in non-medical applications like industrial rubber pads. Hence, this is a medical waste rubber solution.

Rubber-Plastic Composite Waste Recycling

Rubber-Plastic Waste Recycling

Rubber-Plastic Composite Waste Recycling

Rodgers

As much as products of this nature have their usefulness, the components make the entire products less viable than the composite waste rubber-plastic composite products, and the waste streams of such products almost remain unapreciated.

Products of this nature are most times composite products in electronics, automotive, and packaging industries. Rubber-plastic composites are used as packaging films, gaskets for electronic equipment, and the composite insulated wire as rubber-clad plastic sheaths. Rubber-plastic composite products are the encapsulated products that are subjected to waste streams in the industries. Rodger Klimens sees to the recycling of composite rubber-plastic uses advanced mechanical and solvent softening rubber-plastic interfacial bond separation as modified innovative recycling. Such that in smoother separation methods composite products of waste streams are made viable as inter composite.

The mechanical separation of composites and recovery of the solvent for softening rubber is such a closed acquisition loop, and the environmental impact is very low per the designed recycling.

The potential to process rubber-plastic composite materials enhances what the rubber separator machine can do, allowing for further recycling of composite waste.

Low-quality and impure rubber can also be separated by professional rubber separator machines. Low-quality rubber can be challenging for ordinary equipment to process. Low-quality rubber is rubber with uneven composition, reclaimed rubber with excessive impurities, or rubber that has degraded due to long-term storage. Poor quality rubber is also difficult to recycle, but Baixiong Klimens’ rubber separator machine has precision separation modules designed exactly for those challenging situations. Using spectral analysis technology, the machine identifies the valuable components of low-quality rubber and then rubber goes through a series of advanced steps including counter current washing, screening, magnetic separation, and density separation to strip away the impurities layer by layer. The separated rubber can then be used to make low-end rubber products like rubber blocks and rubber buffers. Processing low quality rubber also addresses the problem of low quality rubber waste to maximize resource utilization.

To sum up, the machines manufactured by Baixiong Klimens handle all kinds of rubber, from rubber bound to waste from daily use, to industrial rubber waste, medical waste rubber, rubber waste from vehicles, low grade rubber and rubber-plastic composite materials. Their effectiveness and resource separation capability enhances rubber resource recycling, resource recovery and separation, and aids in environmental protection and the circular economy. With the increase in the need for recycling rubber, the use of these specialized rubber recycling machines will increase.