What Advantages Does a Powder Mixer Have Compared to Traditional Mixing Methods?

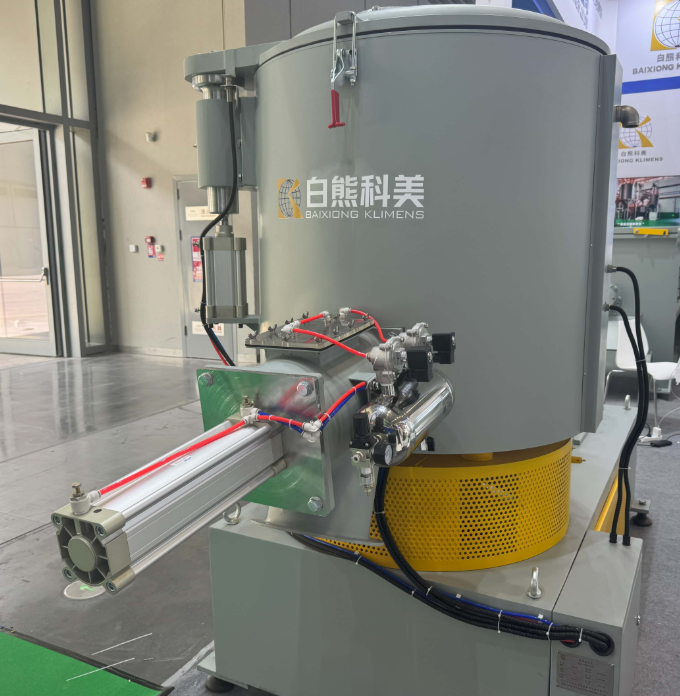

In the food processing, pharmaceuticals, and chemicals industries, the mixing of powders impacts the quality and efficiency of manufacturing. Standard mixing techniques like being stirred by hand or using simple machines provide insufficient precision and efficiency in ever-increasingly complicated processes. More and more industries are adopting the use of powder mixers, which are now seen as professional mixing equipment. BXKM is an example of a company that provides powder mixers. They design and manufacture high quality equipment for a variety of industries. Powder mixers replace and improve processes by optimizing efficiency, which improves competition in the market. This piece will focus on the benefits of incorporating a powder mixer as opposed to using traditional techniques.

Powder Mixer Improves Mixing Efficiency Significantly

The unparalleled mixing efficiency of a powder mixer is a pivotal advantage when compared with traditional techniques of mixing. Compared to manual mixing, which is primarily labor-intensive and time-consuming as one has to stir for hours on end to integrate a large batch of powder, the process is also susceptible to fatigue and, therefore, a slowdown.

In contrast, BXKM’s powder mixers are designed with a robust motor and enhanced mixing blades. As a result, they can mix a large batch of powder materials in a matter of a few minutes, up to half an hour. Certain models with continuous mixing capabilities also allow for non-stop production, increasing an enterprise’s production efficiency. In numerous situations, a powder mixer will cut mixing time by over 70% compared to older, more conventional approaches. This significant decrease in time and mixing efficiency helps enterprises considerably reduce labor and time expenses.

Ensures Efficient and Even Mixing of Powder Materials

Uniformity of powder mixing is crucial. Any powder mixing that fails to achieve this could result in quality variations in the finished product. In the case of a pharmaceutical product, the drug powder contained in the mixture may produce an unevenly effective final product and/or a health risk. Conventional mixing methods provide limited ranges of stirring and unevenly applied forces, resulting in failure to mix in a uniform manner. BXKM’s powder mixer elegantly overcomes this limitation. BXKM designed an advanced mixer with unique multi-directional mixing blades and a proprietary barrel design that produces a unique driven action to achieve many complex motions (rotation, flipping, and shear), and complete the mixing process.

Every piece of powder gets appropriate contact, and mixing uniformity exceeds an astonishing 95%. This is an accomplishment that general powder mixing approaches fail to achieve. Consistency attained with a powder mixer is a guarantee of uniform quality and a lower defect rate.

Reduced Waste with BXKM Powder Mixer

For a lot of enterprises, traditional powder mixing methods are wasteful, which, in turn, is expensive. In manual mixing, operators may spill some of the powder. In simpler mechanical mixers, powder waste gets stuck to the mixer, making it hard to retrieve. BXKM’s powder mixer is designed to cut down on waste. Its powder mixer barrels use a smooth, non-stick design which prevents powder sticking to the walls of the mixer. The waste caster design of the BXKM powder mixer optimally eliminates the discharge of mixed products, ensuring a residual powder rate of under 1%. Some closed models of BXKM powder mixers prevent airborne powder during mixing to avoid waste.

Enterprises save money on materials by cutting down on waste through a powder mixer, as opposed to more traditional methods of mixing.

Powder Mixer Enhances Operational Safety for Workers

Safety is a top priority for any industry, and there are greater risks for workers using traditional methods of mixing. Manual mixing involves a worker being in direct contact with harmful powders. Simple, mechanical mixers are equipped with no safety measures, and workers are injured by the moving parts in the mixer. BXKM powder mixers are designed for safety. Most models have a fully enclosed mixing barrel, so the workers are safely isolated from harmful powders. Other safety features include the ability to stop the mixer if the lid is opened while mixing is in progress. With a fully automated powder mixer, there is a far greater reduction in the direct, manual work required as compared to traditional powder mixing.

Powder Mixer Adapts to Diverse Powder Material Characteristics

Powder materials can significantly vary from industry to industry. Some powders are fine particles that can easily become airborne while others are dense and difficult to mix. Some powders are cohesive and will easily stick to the other particles.

Each traditional mixing method has some limitations on the types of powders it can handle, having to resort to one or two types of powders. BXKM’s powder mixer, on the other hand, can adapt to a variety of powder characteristics. BXKM has several powder mixers, such as the ribbon powder mixer, the cone powder mixer, and the high-speed shear powder mixer. Each powder mixer serves a different purpose; for example, the high-speed shear powder mixer is used for cohesive powders, as it incorporates mixing and breaking up the clumped powder, while the ribbon powder mixer works well for very fine powders, as it prevents the powder from ‘flying’ too much during the mixing. Able to adjust the most time and speed of a powder mixer has made it able to accommodate varying characteristics of different powder materials. This is the type of versatility that no other traditional mixing method can provide, and it is for this reason that it is used across many different industries.

Dependence on Labor and Management Costs are Reduced with Powder Mixers

Mixing powder using traditional techniques consumes a lot of labor. To complete the process, large numbers of workers need to be hired. The final mixing quality is also dependent on the worker’s mixing abilities and their level of responsibility, increasing the labor costs and making personnel management a bigger challenge.

BXKM's automation technology for powder mixers greatly reduces the need for labor. Most of the powder mixers currently available on the market are fully automated. After setting the parameters for the automated process such as the time and speed, and loading in the materials, the machine will complete the entire process of powder mixing. Compared to traditional practices, this reduction in manual labor for mixing surpasses 80%. Moreover, the consistent quality of the powder mixer mitigates the risk of quality discrepancies due to the varying skill levels of operators, preventing human factors from introducing quality control problems. A powder mixer mitigates reliance on labor, enabling businesses to streamline labor control and cut operational costs. This increases the operational efficiency of the entire enterprise.