What Precautions Should Be Taken When Using ABS Recycle Equipment to Ensure Product Quality?

Recycling ABS plastic helps create a circular economy in the plastic processing industry and reduces pollution and the cost of raw material. However, recycling waste ABS materials should be handled very carefully to ensure the recycled material consistently meets the quality requirements of uniform purity, strength, and appearance. Inadequate recycling ABS processing, dead stock, brittle ABS, and color variations make the material unfit for reuse. This leads to a waste of resources and a tarnished reputation for manufacturers dependent on recycled ABS. To avoid these issues, manufacturers should be knowledgeable on the critical protective measures on the use of ABS recycling equipment. This will guarantee product uniformity and the full benefits of recycling ABS.

Proper Sorting and Cleaning of ABS Waste Materials

Scheduling the recycling of ABS is determining the best way to sort and clean materials. There are plenty of materials to source including the industrial and post-consumer waste. Recognizing that these materials can also be contaminated with other Plastics (PP, PE, PVC) and metals as well as paper and dust should also be weighted. This is due to the fact that they can compromise the quality of the recycled ABS. Sorting waste materials into specific ABS grades and cleaning segregated waste to the cure component is very important. This can be achieved with cleaning waste using pressure water jets and biodegradable surfactants especially to the greases, labels, and adhesives. These are contaminants that pose as impurities and while they are present will cause the process to defective. This is the most important step to recycling ABS waste and must not be overlooked.

Drying Treatment to Remove Moisture

Moisture contamination in ABS waste materials can negatively affect the quality of the recycled product. ABS materials are hygroscopic. When processing these materials, moisture can cause the recycled pellets or product to form cracks, bubbles, or rough surfaces. As such, a drying treatment remains a crucial precaution to take before feeding materials into ABS recycling equipment. Depending on the moisture content, ABS waste should be dried in a professional dryer between 80 and 90 degrees Celsius for 2 to 4 hours. Be sure to monitor and check drying moisture content to confirm that a residual moisture content of 0.2% has been achieved. Subsequently, the materials should be used right away or stored in airtight bags to avoid moisture absorption from the atmosphere. Failure to dry these materials can lead to quality irreversible processing issues that cannot be resolved in future steps.

Proper Adjustment Of ABS Recycle Definable Equipment Settings

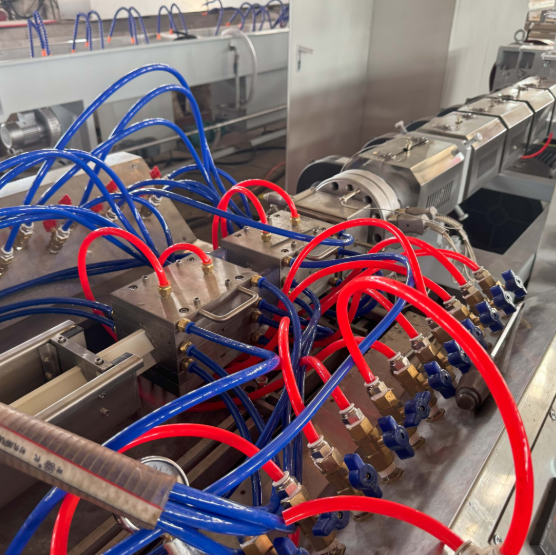

The specific operating parameters directly impact the performance of equipment used for recycling ABS. Thus, properly adjusting the settings becomes the first necessary precaution for maintaining quality. Parameter settings like temperature, speed, and pressure should be tailored per the type of ABS recycling equipment, be it extruders or granulators. For instance, extruders recycling ABS should have operating temperatures between 180 and 220 degrees Celsius. A temperature that is too low will leave a portion of the material that is unmelted. This will cause the pellets to be uneven. A temperature that is too high will cause thermal degradation of ABS, which will reduce the mechanical properties of the material. Materials should be fed to the extruding screw at a matched speed to maintain a constant extrusion rate and uniform material mixing. Furthermore, blockages in the screen changer of the ABS recycling equipment should be monitored and removed to maintain the desired material flow and uniformity in the output. Continuous monitoring and adjusting of equipment parameters helps in maintaining product quality. This should be done based on real time, in situ material and product quality indicators. Operators should have the equipment, and materials, and be positioned to monitor in real time to maintain high product quality according to specific standards and to avoid associated penalties.

Quality Inspection During and After the ABS Recycle Process

Continued quality inspection identifies and solves problems as quickly as possible during the recycling process. Process operators must routinely assess the recycled pellets during processing and check the color uniformity and surface smoothness. Immediate adjustments to the processing equipment or raw material should be made in the case of abnormalities like discoloration, agglomeration of cells, or the presence of impurities. After processing, the product should also undergo thorough testing, which should include tests for mechanical properties and purity to assess tensile strength and impact resistance. Industry testing standards must be met for the recycled material to be incorporated into production. The risks of batch failure in ABS recycling are reduced with routine, systematic inspection.

Regular Maintenance of ABS Recycle Equipment

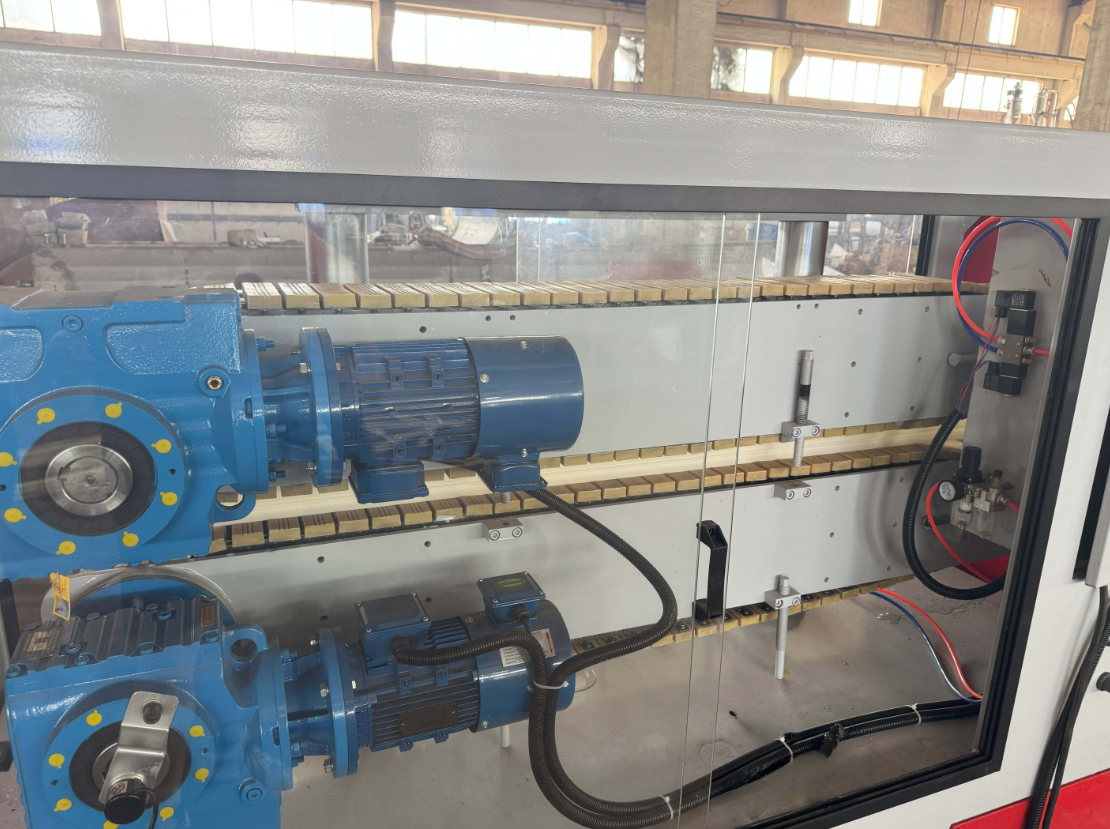

Reliability of ABS recycle equipment is contingent on regular maintenance, which is a fundamental maintenance activity. However, maintenance is often neglected. Over time of equipment operation, wear of screws, barrels, and cutting knives occurs. These worn parts can lead to poor mixing due to incomplete melting and irregular pellet shapes, and consequently affect the quality of the ABS recycle product. It is recommended to establish a routine maintenance schedule that consists of cleaning the equipment after each use, lubricating the moving parts, and periodically changing worn parts of the equipment. Maintenance of these parts also includes the electrical and control systems and should be done to ensure proper parameter control. Adequate maintenance and care will ensure that the performance level of the equipment is consistent and of good quality, in addition to extending the equipment's service life.