Requesting a Call:

+86-13506224031

Online Support

[email protected]

Visit Our Office

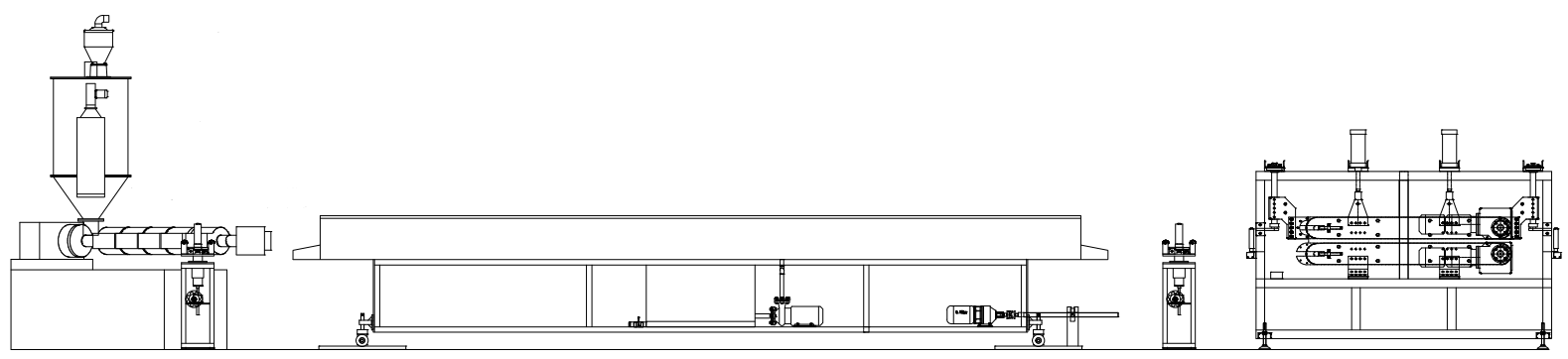

Application of HDPE Extrusion Coating Production Line

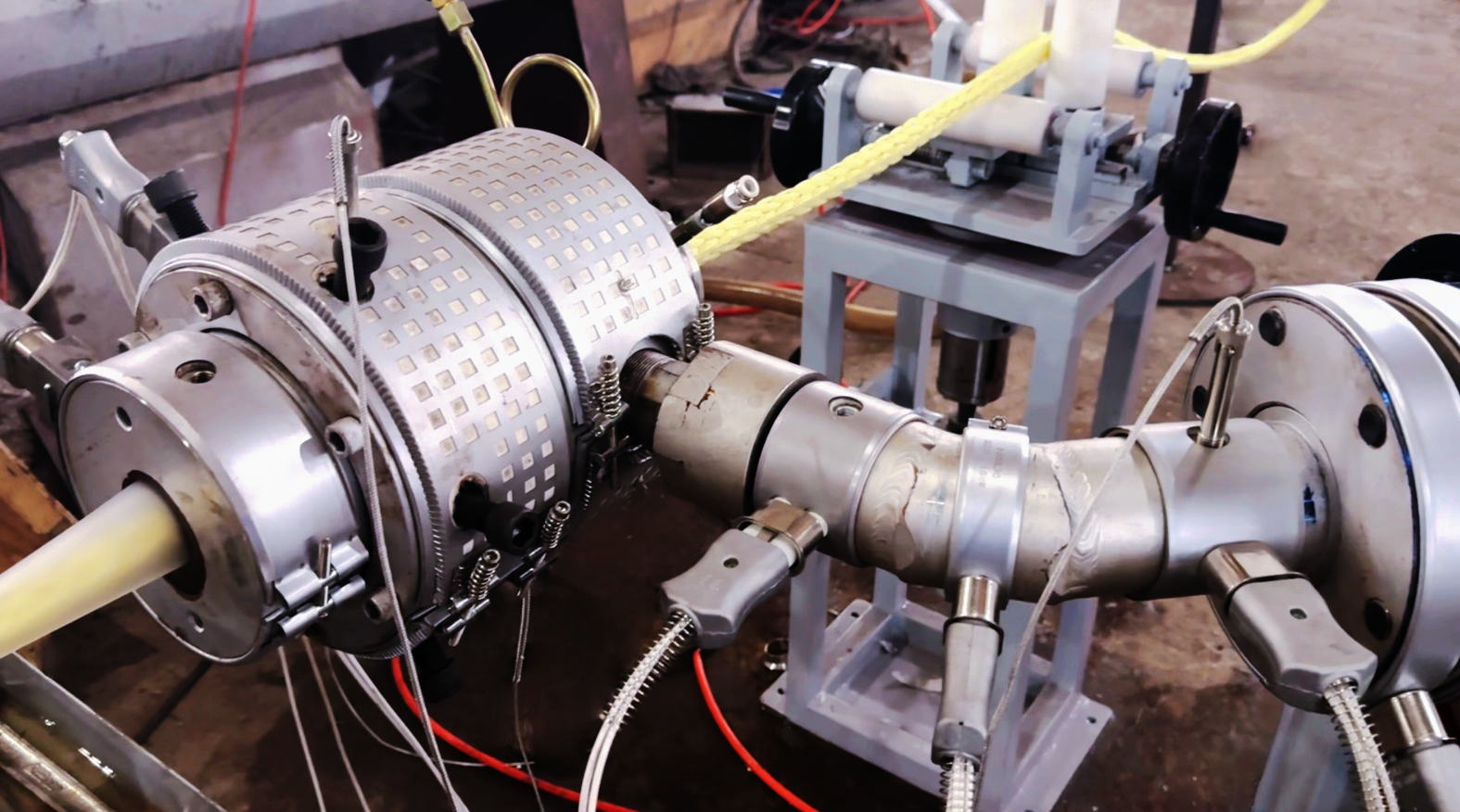

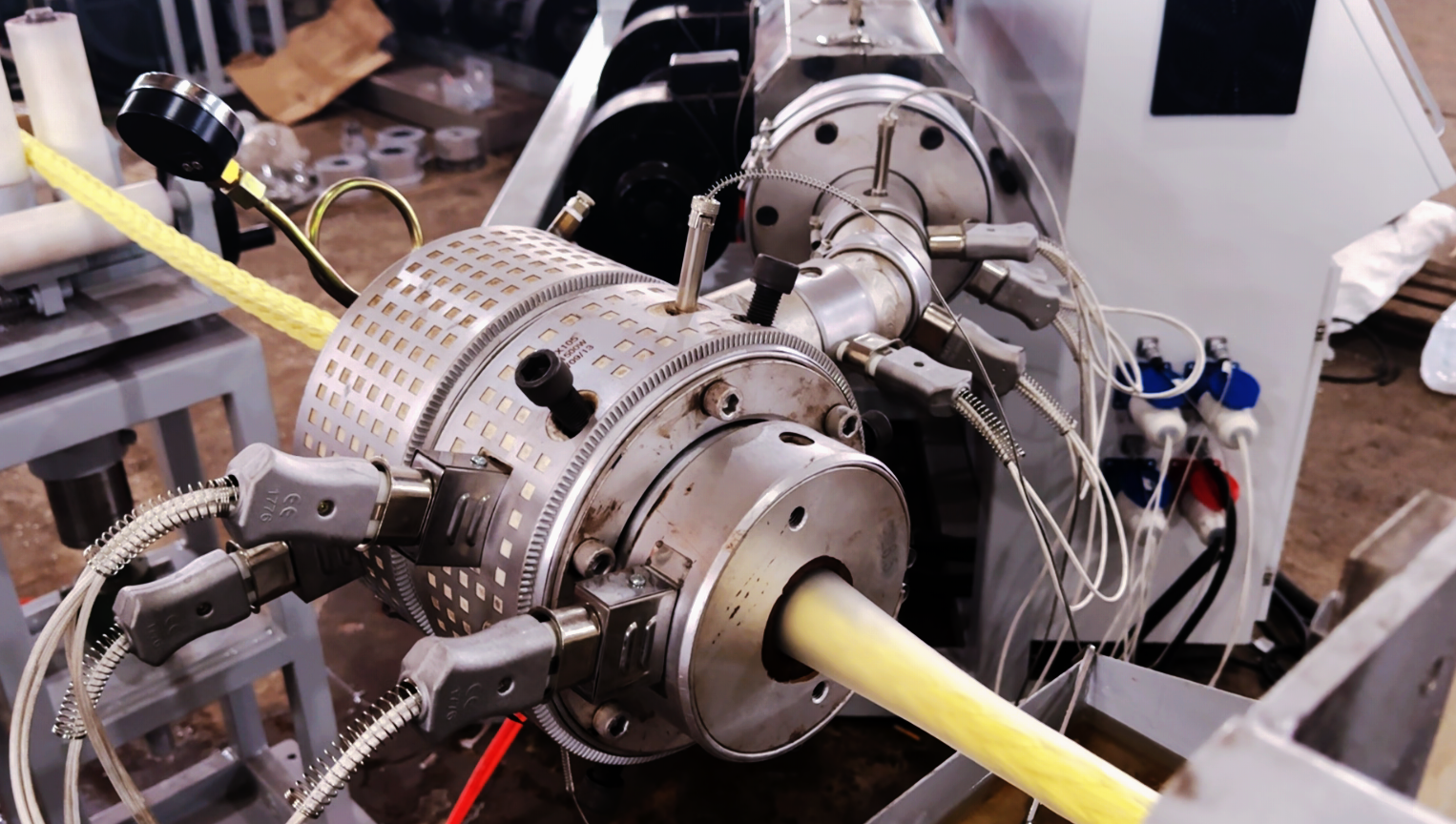

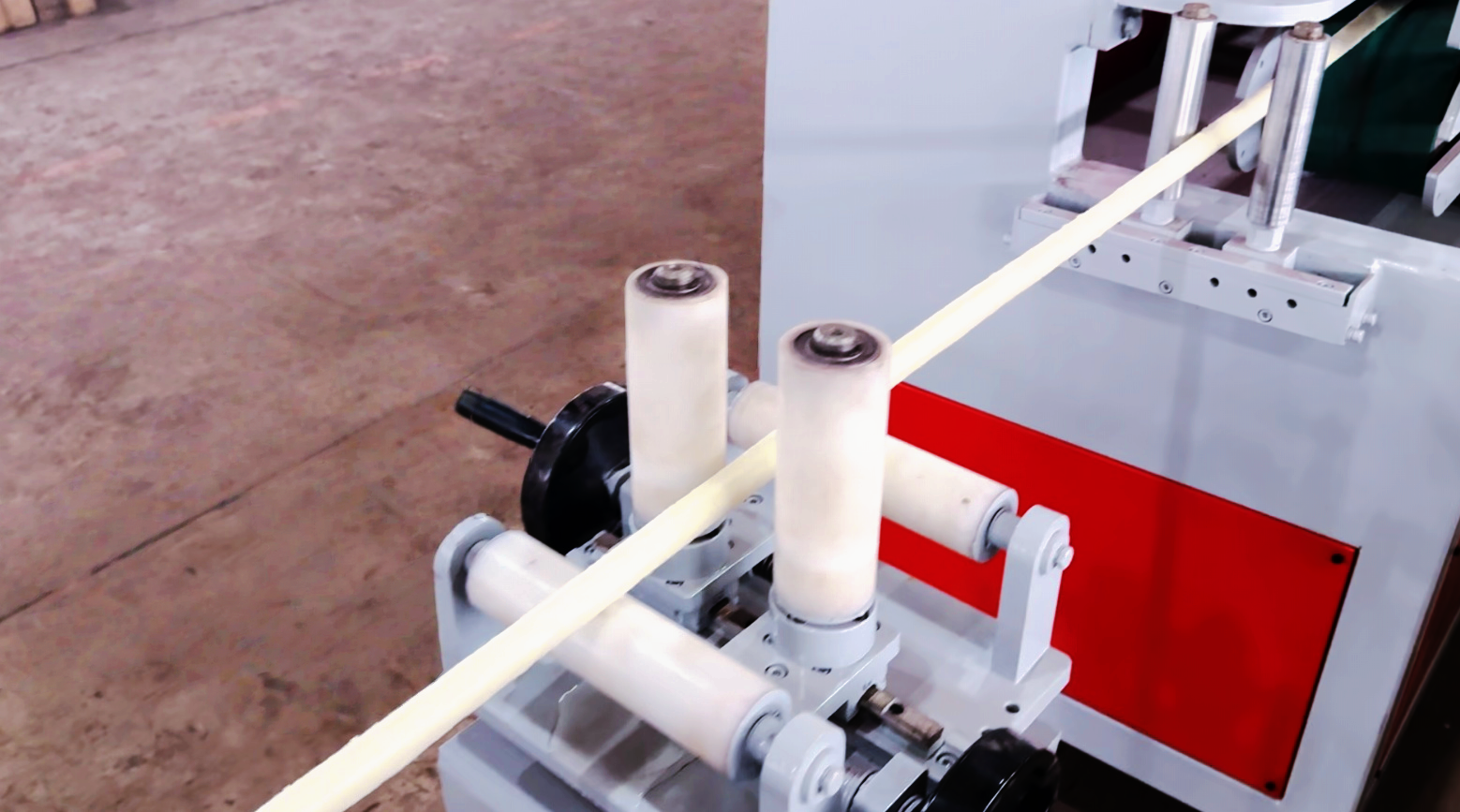

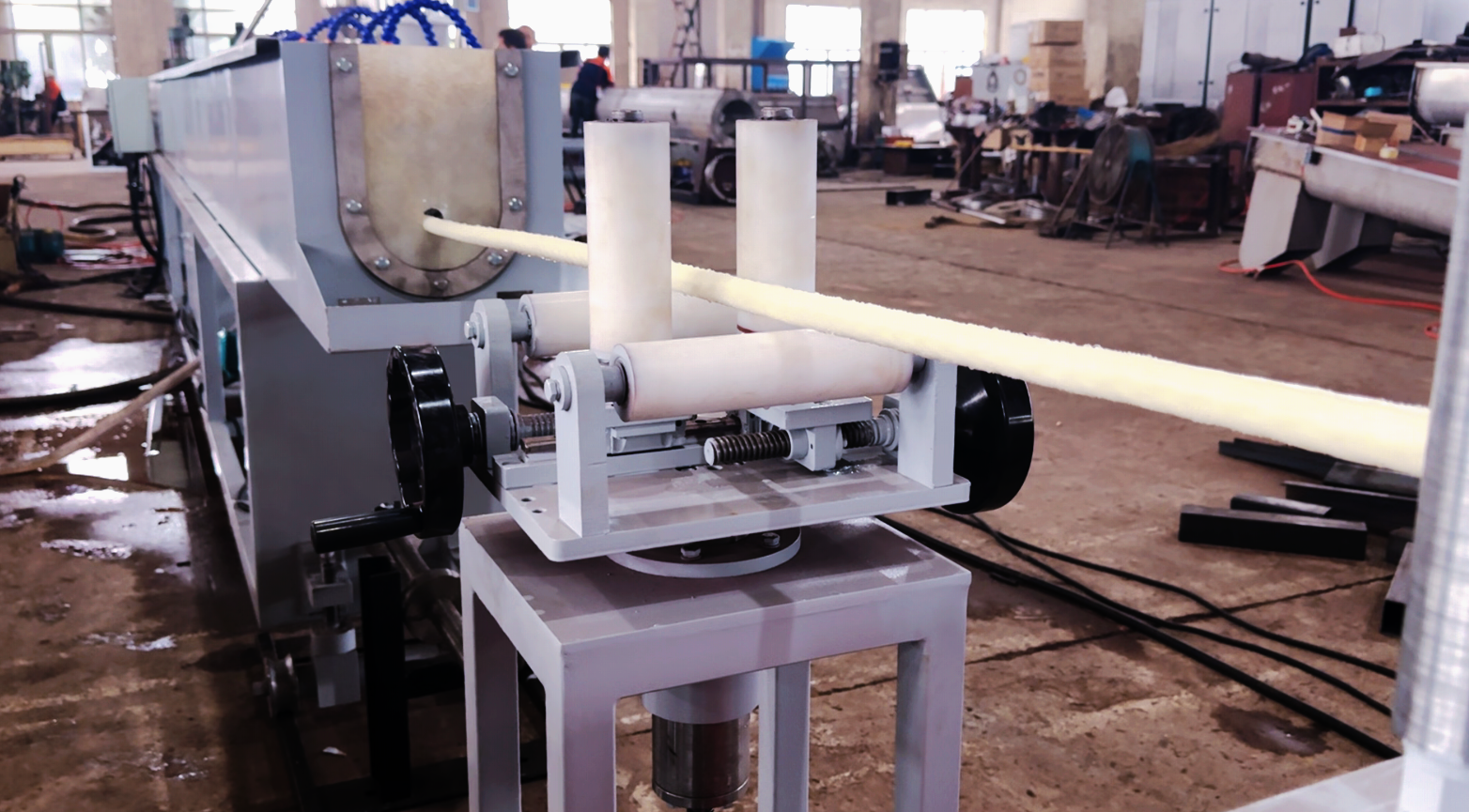

This line is designed to process HDPE pellet raw materials through pre-treatment and melt plasticization, then precisely coat the molten HDPE onto the surface of substrates (such as carbon fiber and metal). After shaping, cooling and traction conveying, it continuously produces HDPE-coated composite parts. It realizes substrate protection, ensures uniform, well-adhered and stably formed coating layers, and achieves efficient and continuous mass production.

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy