Requesting a Call:

+86-13506224031

Online Support

[email protected]

Visit Our Office

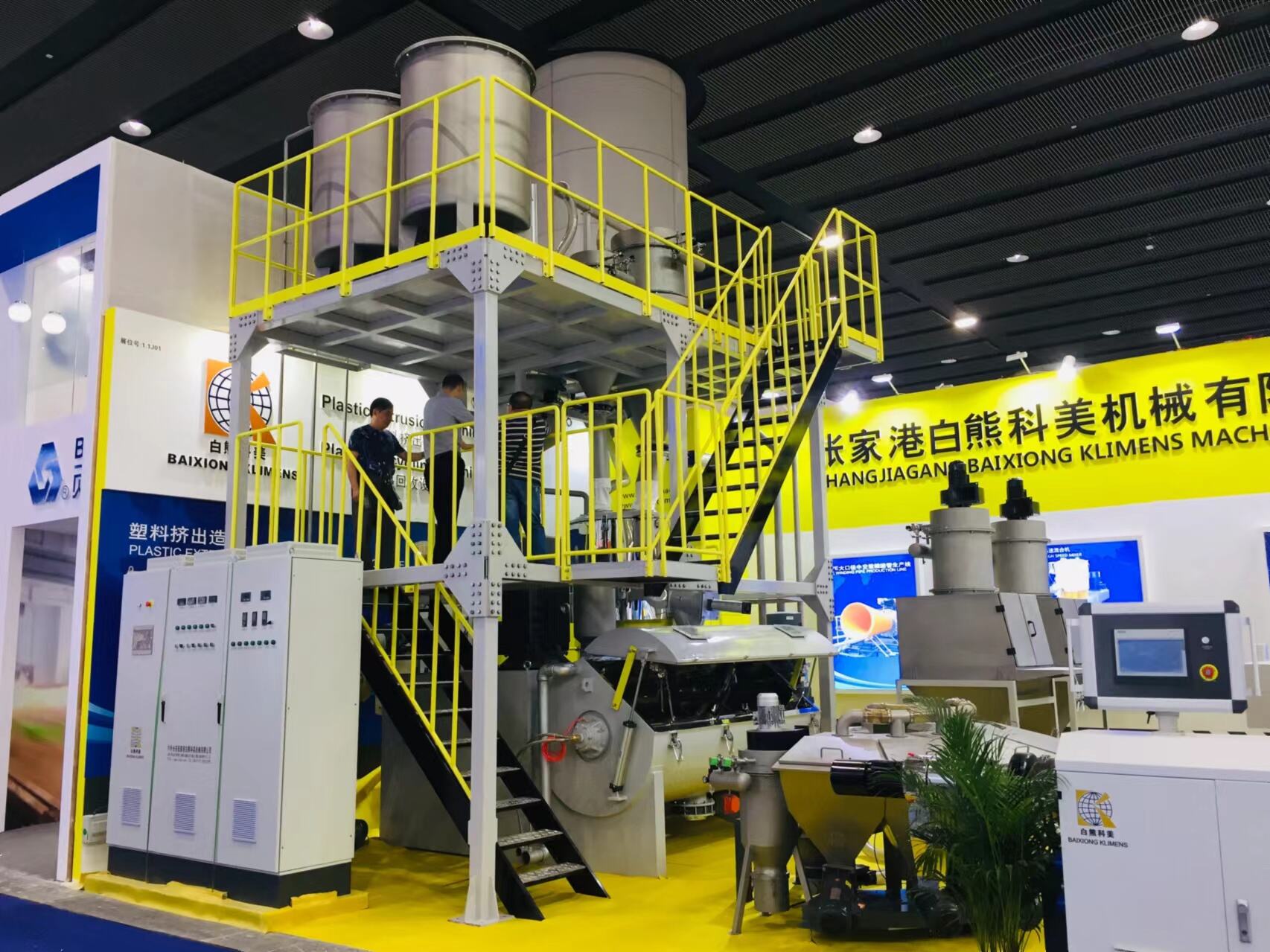

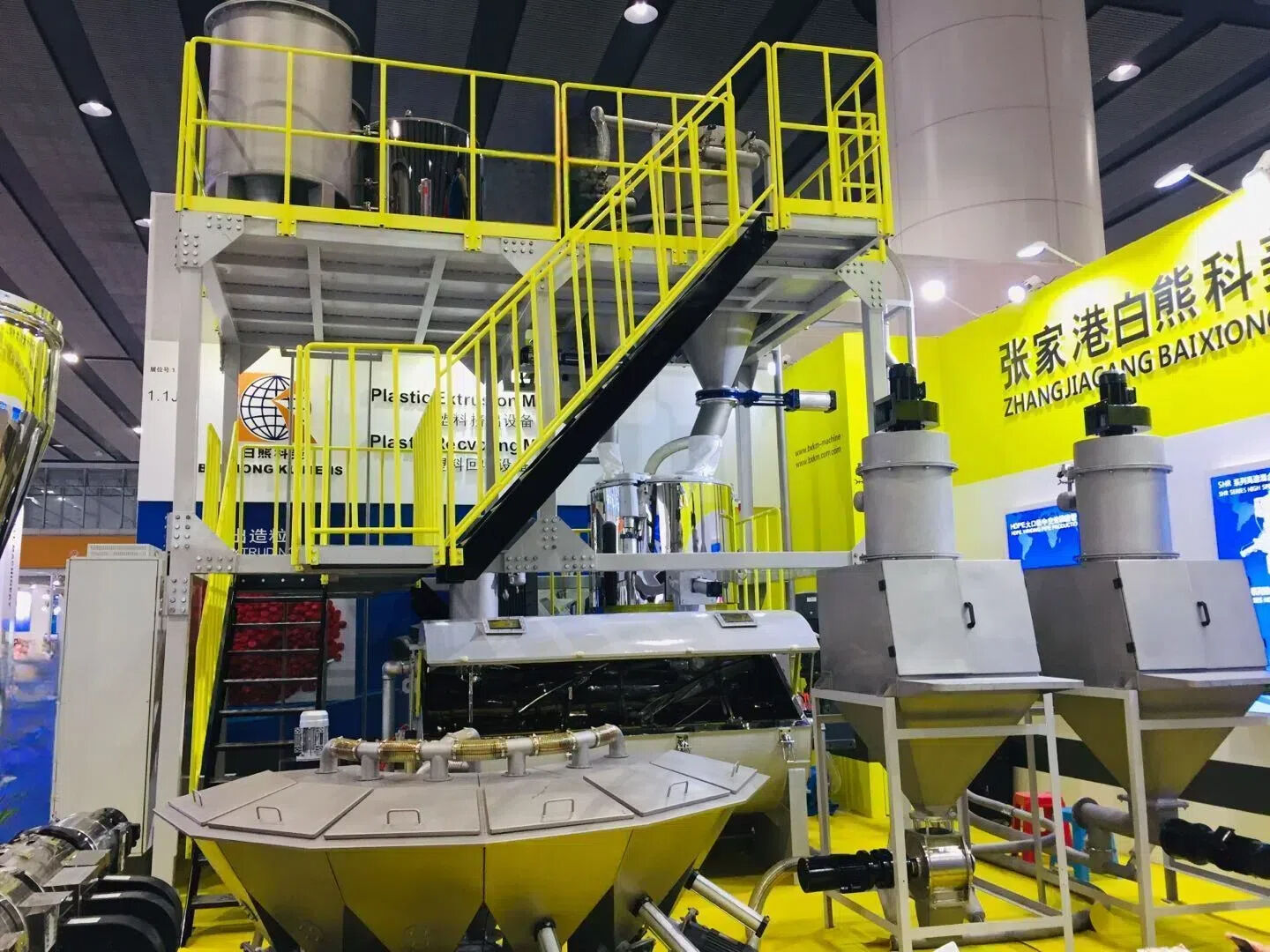

This system is mainly used for the metering, conveying, mixing, and storage of raw materials such as powders, granules, and liquids.

Firstly, powders and granules are conveyed to the electronic scale vacuum hopper via metering screws and negative pressure pneumatic conveying pipelines. Liquid raw materials are conveyed to the electronic scale tank by a gear pump and liquid pipelines. The weight of the raw materials is controlled by imported electronic scale sensors. Finally, the raw materials sequentially enter the mixer for mixing, and the mixed materials are conveyed to the storage silo through screw conveying or negative pressure pneumatic conveying.

The entire system utilizes PLC programming for visual operation. Each detection point in the system is equipped with corresponding sensors for monitoring and signal feedback. Additionally, the system can be programmed according to different customer recipes.

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy