Requesting a Call:

+86-13506224031

Online Support

[email protected]

Visit Our Office

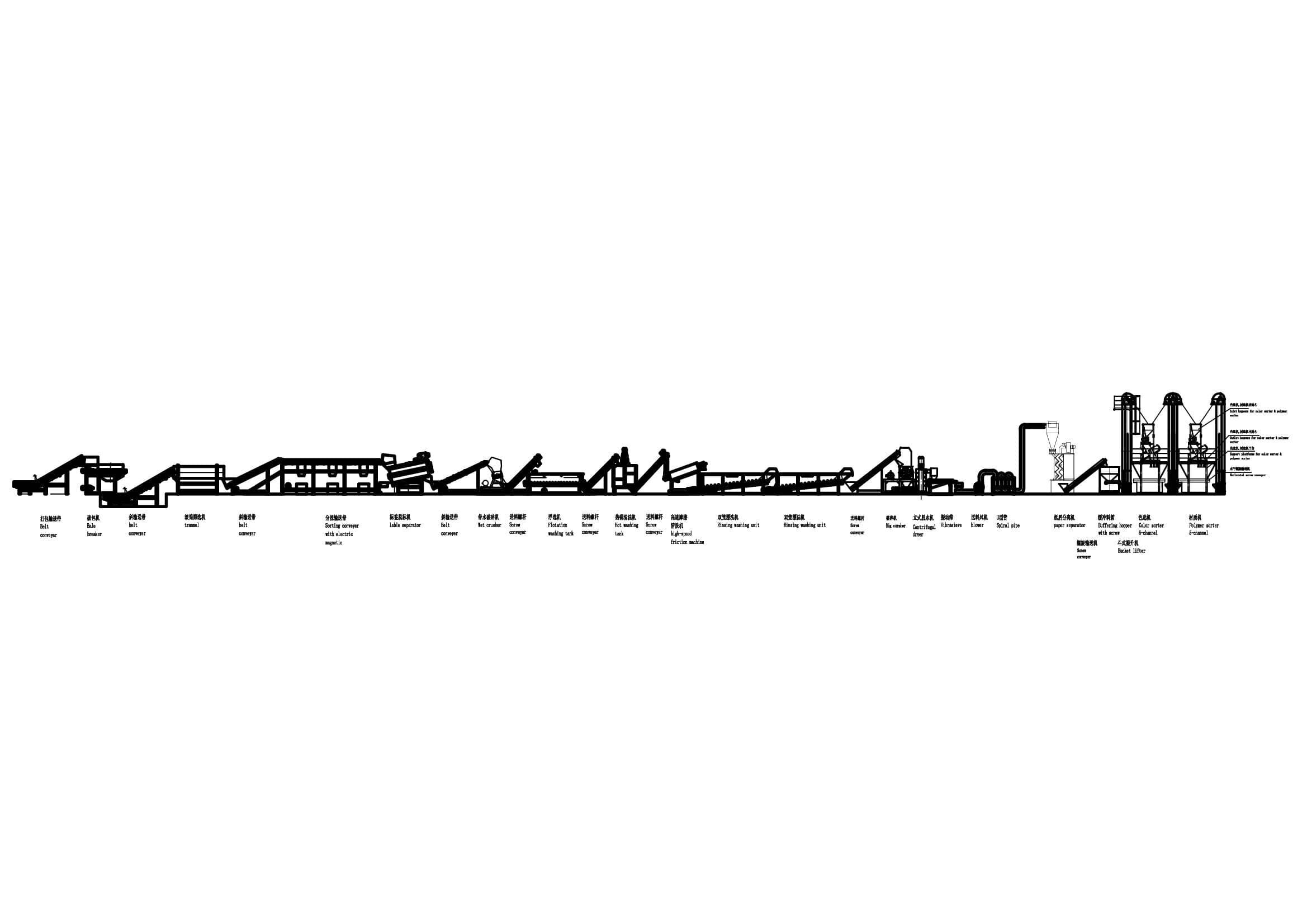

This production line is mainly used to process waste PET plastic bottles (mineral water bottles, beverage bottles). After undergoing label removal, crushing, washing, drying, and film removal processes, the waste PET plastic bottles are processed into high-quality PET bottle flakes.

The production capacity ranges from 300 kg/h to 2000 kg/h and can be configured according to customer requirements.

System configuration

|

Item |

Description |

|

1 |

Inspection Belt Conveyer with Iron Absorber |

|

2 |

Bale Breaker |

|

3 |

Belt Conveyer |

|

4 |

Stones Sorter |

|

5 |

Belt Conveyer |

|

6 |

Label Removing Machine |

|

7 |

Inspection Belt Conveyer |

|

8 |

Belt Conveyer |

|

9 |

Crusher |

|

10 |

Screw Conveyer |

|

11 |

Flotation Tank |

|

12 |

Screw Conveyer |

|

13 |

Hot Washing Tank (with Electric Heating) |

|

14 |

Screw Conveyer |

|

15 |

High Speed Scrubbing Washing Unit |

|

16 |

Flotation Rinsing Unit 1 |

|

17 |

Flotation Rinsing Unit 2 |

|

18 |

Screw Conveyer |

|

19 |

Crusher |

|

20 |

Centrifugal Dryer |

|

21 |

Vibrosieve (Powder Dust Separator) |

|

22 |

Electric Heating Drying Unit |

|

23 |

Small Paper and Label Separator |

|

24 |

Silo |

|

25 |

Electric Control Cabinet |

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy