Requesting a Call:

+86-13506224031

Online Support

[email protected]

Visit Our Office

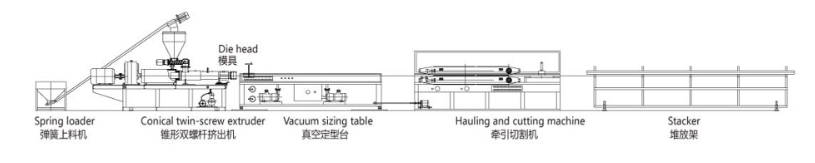

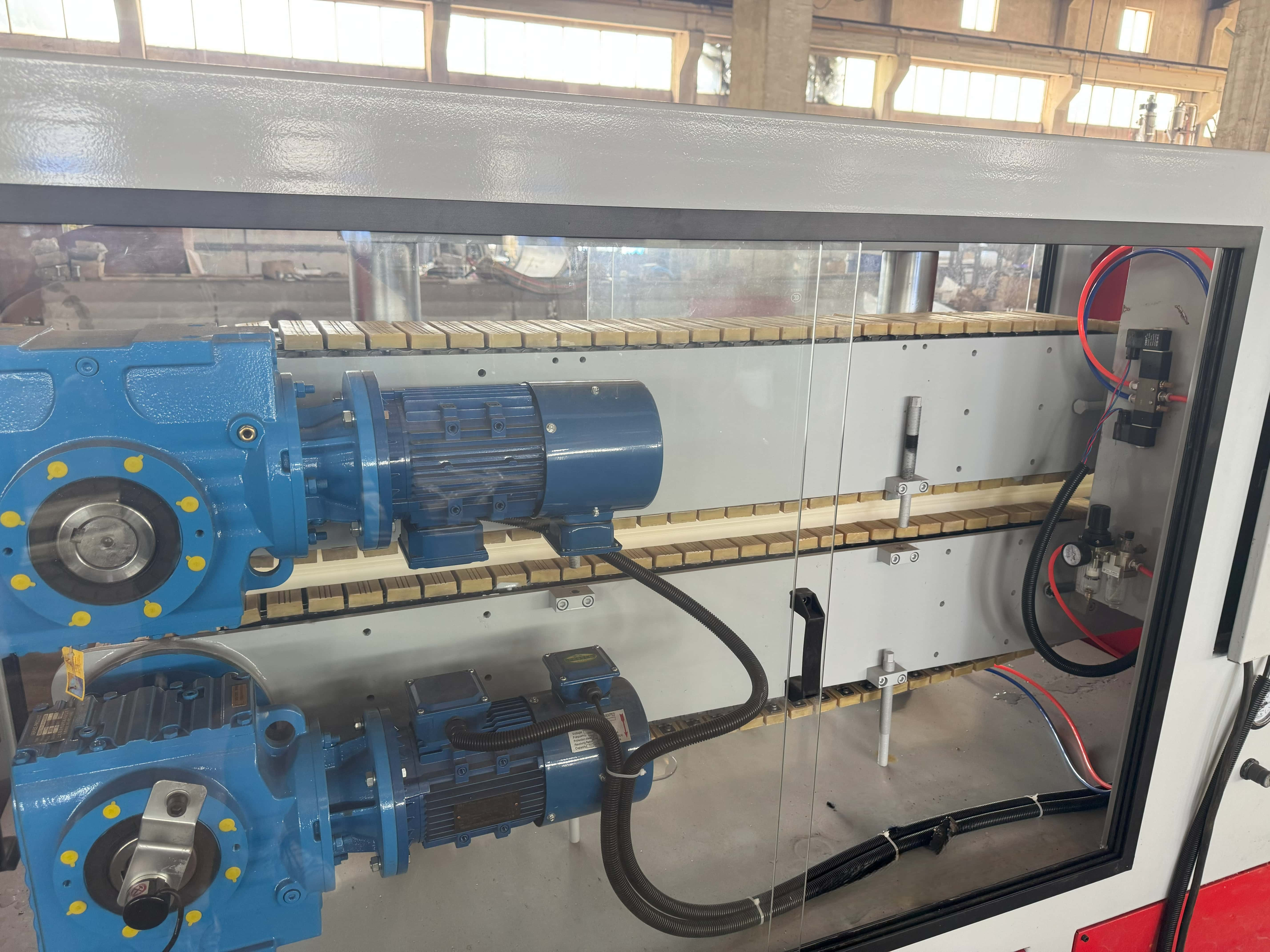

The ABS profile extrusion production line is a specialized set of equipment used to produce products with complex cross-sectional shapes (such as special-shaped pipes, profiles, decorative strips, etc.) through the extrusion molding process using ABS (Acrylonitrile Butadiene Styrene copolymer) raw materials. Its core process involves heating and melting, pressurizing and extruding, shaping, and cooling to transform granular raw materials into continuous profile products. It is widely used in automotive, home appliances, construction, medical devices, and other industries.

Material Adaptability

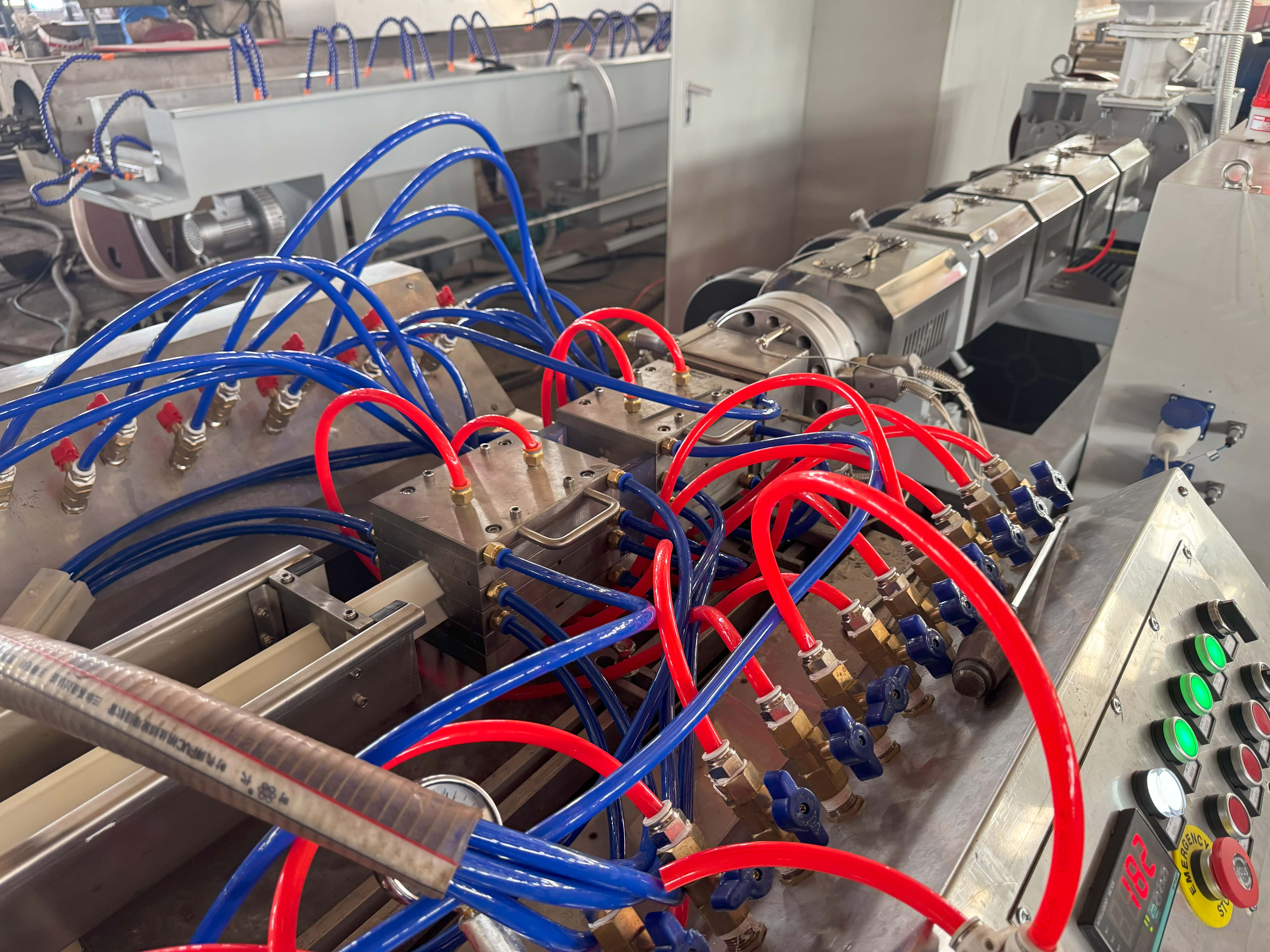

Optimized for ABS's high impact strength and excellent processability, the screw compression ratio and mold flow channels are designed to ensure stable melt flow and minimize internal stress (preventing post-production deformation of the product).

Dimensional Accuracy Control

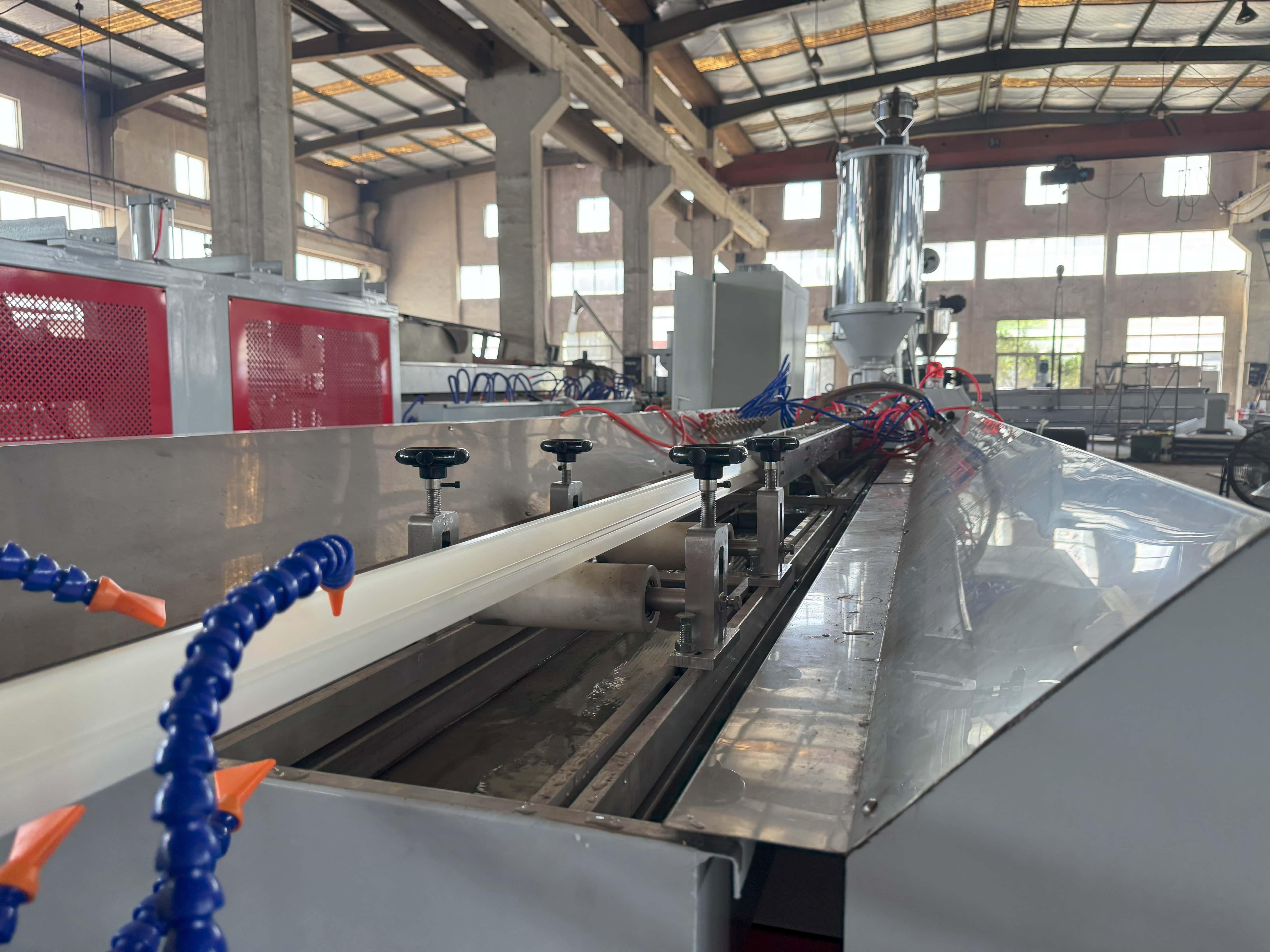

The coordination between the calibration mold and haul-off speed is critical. Through precise control of vacuum level, cooling water temperature, and haul-off tension, the cross-sectional dimensional tolerance (e.g., ±0.1mm) and straightness (≤1mm/m) of the profile are ensured.

High Efficiency & Energy Saving

Equipped with zoned heating (independent temperature control for the barrel and mold) and thermal insulation design to reduce heat loss. Some machines feature variable-frequency motors to adjust power consumption based on production output.

Flexibility

Mold replacement enables the production of profiles with different cross-sections, supporting small-batch, multi-variety production needs. Some production lines are compatible with co-extrusion of ABS and other materials (e.g., PC/ABS blends).

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy